Here’s how we make our minimalist bifold.

We use traditional techniques with leather from some of the highest regarded tanneries in the world to produce an item that is built to last for many years and age beautifully.

Below, I’m using Pueblo from the Badalassi Carlo tannery in Italy. It’s a vegetable tanned leather that has a slightly roughed up surface that gives it its distinctive, vintage look. These fibers will compact over time, giving it a great looking sheen.

These are the hand tools I’ll be using in making the wallet.

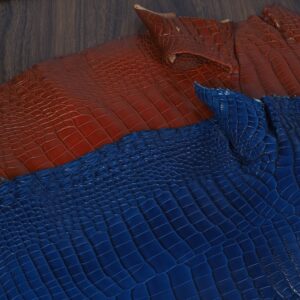

Leather is selected and pieces are cut. The exterior is the ortensia color, a stunning blue-green, and the interior is the cognac color.

The “T-slot” is thinned down with a French edger to reduce bulk.

Pockets are creased.

Edges are beveled and burnished.

Bevelling removes a thin strip of leather, rounding the edge.

Burnishing is a process of using friction to compact the fibers. It’s only possible to burnish vegetable tanned leather. Pueblo burnishes beautifully, becoming quite glassy.

I use water, CMC, and mill wax in the edge finishing. Varying grits of sandpaper are also essential in achieving a super smooth edge.

Pockets are glued to panels.

T-slot is sewn to panel.

Pocket is glued beneath T-slot, and left side is trimmed. Trimming provides a perfectly smooth edge, which will greatly aid in edge finishing.

Pocket is sewn on. The edge is then creased, beveled, and burnished as before.

Lining is glued to body.

Panels are glued on to body, and the wallet is trimmed to size.

Stitching holes are made.

Wallet is saddle stitched. Saddle stitching is a method of using two needles to achieve a very strong stitch that won’t unravel if a thread is cut.

Outer edges are creased, beveled, and burnished.

The wallet is finished.

Thanks for taking a look at our build process!